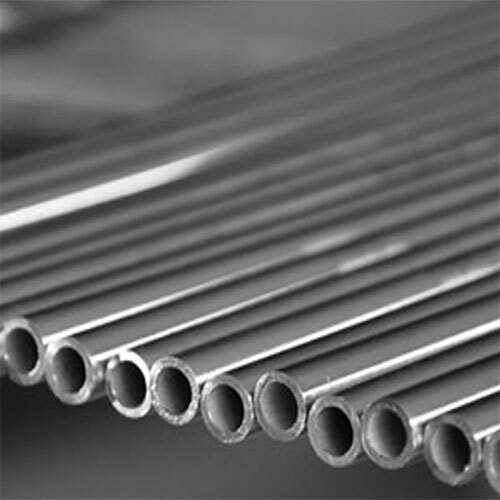

304 Stainless Steel Pipes

Price 250.0 INR/ Kilograms

304 Stainless Steel Pipes Specification

- Shape

- Round

- Surface Finish

- Steel Finish

- Usage

- Industrial

- Application

- Industrial

- Product Type

- 304 Stainless Steel Pipes

- Material

- Stainless Steel

- Material Grade

- A

- Section Shape

- Round

- Thickness

- 0.5-8 Millimeter (mm)

- Length

- 3 Meter (m)

304 Stainless Steel Pipes Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 1000 Kilograms Per Day

- Delivery Time

- 7 Days

About 304 Stainless Steel Pipes

304 stainless steel pipes area versatile and widely used austenitic alloy, often called "18/8" due to their composition of 18% chromium and 8% nickel. Known for excellent corrosion resistance, high tensile strength, and durability, they perform well across extreme temperatures. They are easily fabricated and welded, with non-magnetic properties in their annealed state. Common applications include food processing equipment, chemical pipelines, and architectural frameworks, though grade 316 is preferred in high-chloride marine environments.Superior Material Quality

Made with high-quality 304 stainless steel (Grade A), these pipes offer excellent resistance to corrosion and rust, making them ideal for demanding industrial environments. The even thickness and round shape ensure stability and consistent performance during operation, while the steel finish provides a sleek, uniform appearance.

Precision Engineering

With a thickness range of 0.58 mm and a precise length of 3 meters, each pipe is crafted to meet rigorous industrial standards. The round section shape is engineered for strength and ease of installation, making these pipes suitable for a wide array of industrial usage scenarios.

Flexible Industrial Applications

These 304 stainless steel round pipes are highly sought after across multiple sectorswhether youre a dealer, manufacturer, or supplier, their versatility benefits various projects. Their adaptable size and superior material grade make them a dependable choice for structural frameworks, fluid transport, or mechanical systems.

FAQs of 304 Stainless Steel Pipes:

Q: How are 304 stainless steel pipes with a steel finish manufactured for industrial use?

A: These 304 stainless steel pipes are produced through precise processes involving slitting, forming, and welding top-grade stainless steel sheets. The steel finish is achieved by specific surface treatments, creating pipes that are not only robust but also resistant to corrosion, making them suitable for intensive industrial environments.Q: What makes Material Grade A important for these pipes?

A: Material Grade A signifies the pipes are made from top-quality 304 stainless steel, ensuring optimal corrosion resistance and durability. This grade is preferred in industries that require reliable performance under harsh conditions and frequent operational demands.Q: When should I choose stainless steel round pipes for my project?

A: You should opt for these 304 stainless steel round pipes when your application requires high resistance to corrosion, consistent thickness (0.58 mm), and reliable structural strength. Their 3-meter length and round shape offer flexibility for various industrial setups.Q: Where are these 304 stainless steel pipes commonly used?

A: These pipes are widely employed in industrial sectors such as chemical processing, water supply, construction frameworks, and mechanical systems across India. Their resilience and quality make them a favorite among distributors, exporters, and manufacturers.Q: What is the typical process for installing these round stainless steel pipes?

A: Installation generally involves cutting the pipe to the required length, fitting using appropriate connectors or welding, and securing it within the systems framework. The pipes standard dimensions simplify both assembly and integration with existing infrastructure.Q: How do these pipes benefit industrial operations?

A: These 304 stainless steel pipes provide longevity and reduced maintenance costs due to their excellent resistance to rust and oxidation. The high-grade material ensures less downtime and fewer replacements, offering cost-effective and reliable performance in demanding settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Pipes And Tubes Category

304L Stainless Steel Pipe

Price 350.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Material Grade : A

Material : Stainless Steel

Product Type : Other, 304L Stainless Steel Pipe

Usage : Industrial

Stainless Steel Polished Pipe

Price 350.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Material Grade : A

Material : Stainless Steel

Product Type : Other, Stainless Steel Polished Pipe

Usage : Industrial

Stainless Steel Pipe

Price 250.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Material Grade : A

Material : Stainless Steel

Product Type : Other, Stainless Steel Pipe

Usage : Industrial

Aluminium Alloys Tube

Price 850.0 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Material Grade : A

Material : Aluminium

Product Type : Other, Aluminium Alloys Tube

Usage : Industrial

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry