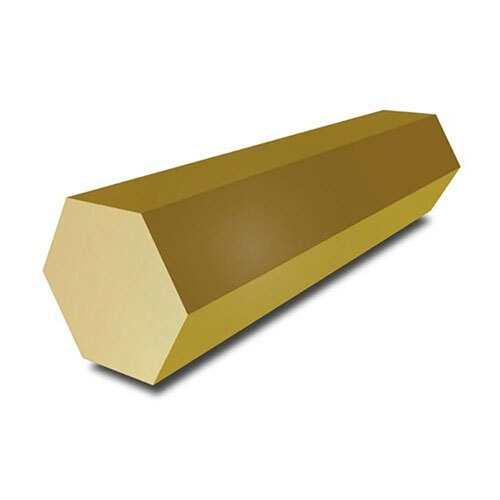

Brass Extrusion Rod

Price 925.0 INR/ Kilograms

Brass Extrusion Rod Specification

- Usage

- Industrial

- Application

- Industrial

- Surface Finish

- Polished

- Shape

- Round

- Type

- Brass Extrusion Rod

- Material Grade

- A

- Material

- Brass

Brass Extrusion Rod Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Supply Ability

- 1000 Kilograms Per Day

- Delivery Time

- 7 Days

About Brass Extrusion Rod

Wieland Chase employs brass extrusion,a hot deformation process that involves pushing heated brass billets through a die to make a desired shape and size of a brass rodA brass extrusion rod is a solid or hollow metal bar made primarily of copper and zinc, manufactured by forcing a heated brass billet through a shaped die. This process creates uniform dimensions and a precise profile, such as round, hexagonal, or square shapes. Known for its excellent machinability, corrosion resistance, and good tensile strength, the extruded rod is a versatile material used across many industries. Common applications include manufacturing fasteners, automotive parts, plumbing fittings, electrical connectors, and decorative hardware. The specific properties, like hardness and workability, can be tailored by adjusting the alloy composition.Superior Quality and Durability

Our Brass Extrusion Rods are manufactured using Grade A brass, ensuring exceptional strength and longevity. The polished finish not only adds aesthetic appeal but also reinforces resistance to corrosion, making these rods highly suitable for critical industrial settings.

Versatile Industrial Applications

These round brass rods are tailored for diverse industrial uses, from manufacturing components to being integrated into heavy machinery. Their adaptable form and dependable material grade enable seamless incorporation into various production and engineering workflows.

FAQs of Brass Extrusion Rod:

Q: How is the Brass Extrusion Rod manufactured?

A: Brass Extrusion Rods are produced using a specialized extrusion process where Grade A brass is heated and forced through a die to achieve the desired round shape and polished finish. This ensures uniformity, strength, and excellent surface quality.Q: What are the main applications of this Brass Extrusion Rod?

A: These rods are primarily used in industrial environments for manufacturing, engineering, and machinery components. Their robust and corrosion-resistant properties make them ideal for use in sectors requiring reliable metal materials.Q: When should I choose a polished Brass Extrusion Rod for my project?

A: A polished Brass Extrusion Rod is recommended when both aesthetic appeal and resistance to tarnish or corrosion are essential. Choose this rod for applications that demand a clean, professional finish and durability over time.Q: Where can I purchase Brass Extrusion Rods in India?

A: Brass Extrusion Rods are available through a widespread network of dealers, distributors, exporters, importers, manufacturers, suppliers, traders, and wholesalers throughout India, catering to both small and large scale industrial needs.Q: What is the process for sourcing these rods from manufacturers?

A: You may contact manufacturers directly or work through suppliers and traders. After specifying your requirements, trusted manufacturers offer customizations if needed and ensure deliveries that meet industrial standards.Q: How does using high-grade Brass Extrusion Rods benefit my industry?

A: Utilizing these rods ensures enhanced durability, reliable performance, and longevity in your industrial applications. The material grade and polished surface guarantee low maintenance costs and extended operational life for components.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metal Bar And Rod Category

SS316 Round Bar

Price 350.0 INR / Long Ton

Minimum Order Quantity : 100 Long Tons

Application : Industrial

Surface Finish : Polished

Material : Stainless Steel

Material Grade : A

Stainless Steel Nitronic 50 Round Bar

Price 1000.0 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Application : Industrial

Surface Finish : Polished

Material : Nitronic

Material Grade : A

Tungsten Round Bar

Price 8000.0 INR / Kilograms

Minimum Order Quantity : 2 Kilograms

Application : Industrial

Surface Finish : Polished

Material : Tungsten

Material Grade : A

Brass Hex Bar

Price 850.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Application : Industrial

Surface Finish : Polished

Material : Brass

Material Grade : A

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry