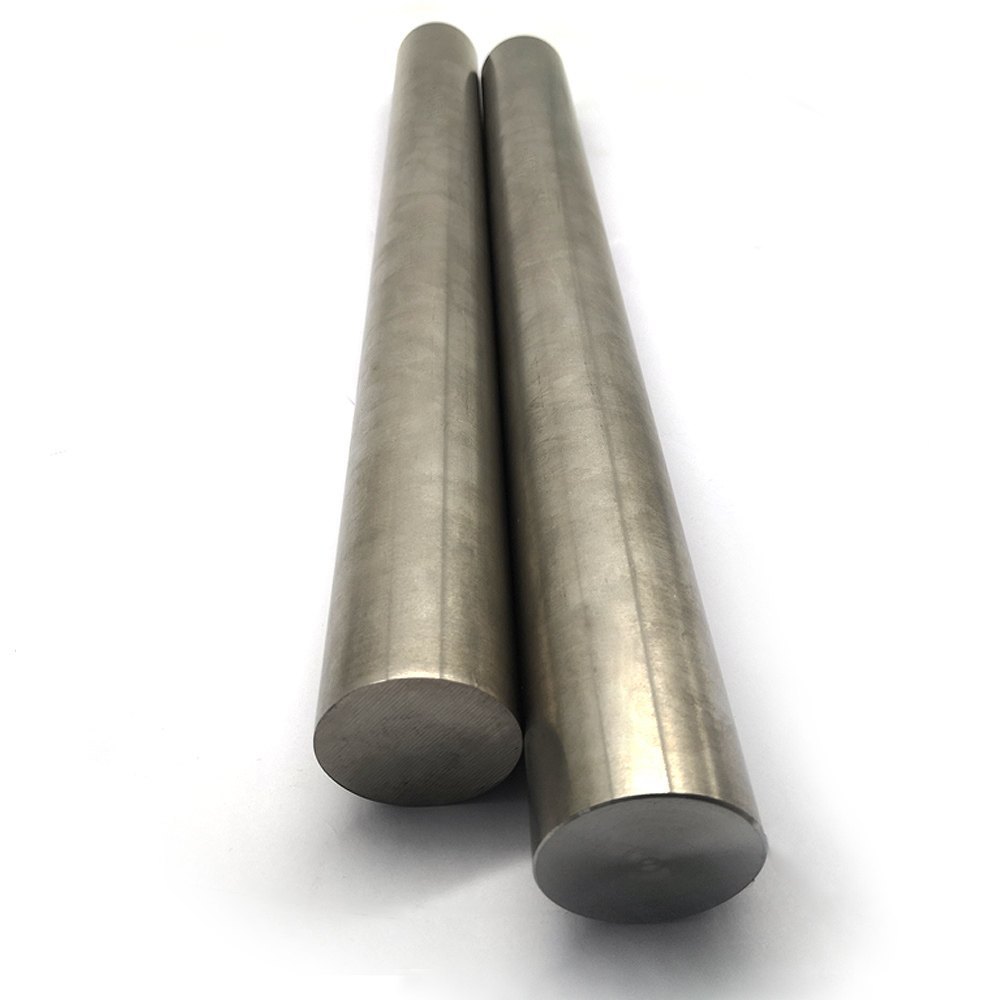

Carbon Steel Bar

Price 90.0 INR/ Kilograms

Carbon Steel Bar Specification

- Diameter

- 3-300 Millimeter (mm)

- Material Grade

- A

- Shape

- Round

- Material

- Carbon Steel

- Type

- Carbon Steel Bar

- Application

- Industrial

- Surface Finish

- Polished

Carbon Steel Bar Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Supply Ability

- 1000 Kilograms Per Day

- Delivery Time

- 7 Days

About Carbon Steel Bar

Carbon steel isan iron-carbon alloy where carbon is the primary alloying element, with properties primarily determined by its carbon content.It can contain small amounts of other elements like manganese and silicon but lacks significant amounts of other alloying elements likechromium.The amount of carbon content classifies carbon steel into different grades, such as low, medium, high, and ultra-high carbon steel, which vary in hardness, strength, and ductility.A carbon steel bar is a versatile and cost-effective metal alloy primarily composed of iron and carbon. Its properties vary based on carbon content, typically categorized into low, medium, and high-carbon types. Low-carbon steel is soft and ductile, making it easy to form and weld for applications like structural components and sheets. Medium-carbon steel offers a balance of strength, hardness, and ductility, suitable for automotive and machinery parts. High-carbon steel is exceptionally hard and wear-resistant, used for springs and high-strength wire. Bars come in various shapes, including round, square, flat, and hex, serving a wide range of construction and manufacturing needs.Superior Strength and Versatility

Crafted from high-grade carbon steel, these bars deliver outstanding strength and long-lasting performance. Their round profile and wide diameter range make them suitable for numerous industrial uses, including construction, fabrication, and machinery manufacturing.

Polished Surface Finish Advantage

The polished surface enhances corrosion resistance and provides an appealing aesthetic, reducing the need for further finishing. This finish ensures that the bars are suitable for visible applications where the look and surface quality are important.

FAQs of Carbon Steel Bar:

Q: How is the carbon steel bar with polished surface finish typically used in industrial applications?

A: Polished carbon steel bars are commonly utilized in industries for manufacturing machine components, shafts, fasteners, and fabrications where a smooth surface and precise dimensions are critical. Their strength and finish make them ideal for heavy-duty and visible installations.Q: What benefits does material grade A offer in carbon steel round bars?

A: Material grade A provides superior mechanical properties, excellent workability, and consistent strength. This ensures reliable structural integrity and performance, making it suitable for high-stress industrial settings.Q: When should I choose a polished surface finish for carbon steel bars?

A: Opt for polished bars when you need enhanced resistance to corrosion, a visually appealing surface, or components for applications where aesthetics and cleanliness are important, such as architectural or exposed machinery parts.Q: Where are these carbon steel bars available in India?

A: These bars are widely available across India through authorized dealers, distributors, exporters, importers, manufacturers, suppliers, traders, and wholesalers. You can source them in most major industrial markets and supply hubs.Q: What is the manufacturing process of a polished carbon steel bar?

A: The process involves forming the bar from carbon steel using rolling or forging, followed by precision machining. The surface is then polished using abrasive methods to achieve the required smoothness and shine, ensuring minimal surface imperfections.Q: How does the diameter range of 3-300 mm benefit users?

A: With a broad diameter selection, users have the flexibility to select bars that match their exact needs, from small precision components to large structural elements, making these bars highly versatile for diverse industrial purposes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metal Bar And Rod Category

Phosphor Bronze Rod

Price 1100.0 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Surface Finish : Polished

Application : Industrial

Material : Phosphor Bronze

Material Grade : A

Stainless Steel Rod

Price 225.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Surface Finish : Polished

Application : Industrial

Material : Stainless Steel

Material Grade : A

SS316 Round Bar

Price 350.0 INR / Long Ton

Minimum Order Quantity : 100 Long Tons

Surface Finish : Polished

Application : Industrial

Material : Stainless Steel

Material Grade : A

17-4 PH SS Round Bar

Price 850.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Surface Finish : Polished

Application : Industrial

Material : Stainless Steel

Material Grade : A

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry