Call: 08071793897

Price 750.0 आईएनआर/ Kilograms

MOQ : 100 Kilograms

Specification

- सतह की फ़िनिश

- Polished

- उपयोग

- Commercial

- मटेरियल

- Copper Nickel

- स्टैण्डर्ड

- सतह का उपचार

- साइज

- Standard

Trade Information

- Minimum Order Quantity

- 100 Kilograms

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- दिन

- मुख्य घरेलू बाज़ार

About

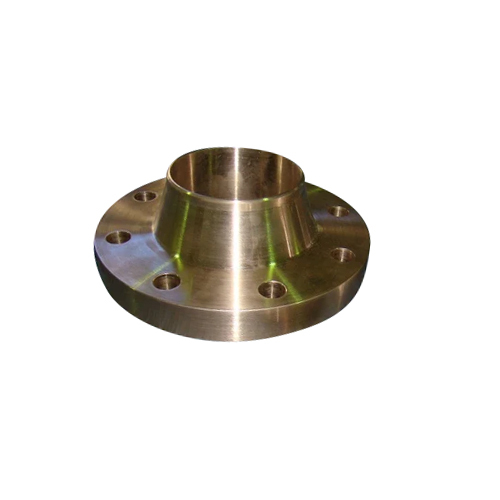

Copper Nickel 90-10 Forged Fittings arehigh-strength, durable components used in piping systems, primarily for marine, oil, and gas applications due to their excellent resistance to corrosion, erosion, and chloride stress cracking, even in seawater.Composed of 90% copper and 10% nickel, with added iron and manganese, this alloy offers exceptional mechanical strength, high-temperature performance, and flexibility.These forged fittings, including elbows, tees, and couplings, are essential for reliable, long-lasting performance in demanding environments, ensuring the integrity of fluid and gas transfer systems.

-

An alloy primarily of 90% copper and 10% nickel, with trace amounts of iron and manganese that enhance its strength and corrosion resistance.

-

Exhibits outstanding resistance to chloride-induced corrosion and pitting, making it ideal for marine and seawater applications where other materials fail.

-

Possesses excellent tensile and yield strengths, along with good toughness, allowing it to withstand high temperatures and stresses.

-

Forged fittings are manufactured by shaping the alloy under high pressure, resulting in superior strength and integrity compared to cast or other forms.

-

Extensively used in oil and gas, power generation, marine (including boat building and seawater piping), and HVAC industries.

-

Available in various forms like elbows, tees, couplings, and unions, manufactured to specific standards such as ASME.

Superior Material Strength

Crafted from Copper Nickel alloy (90% copper, 10% nickel), these forged fittings exhibit excellent mechanical strength and remarkable resistance to corrosion, especially against sea water and industrial chemicals. This makes them ideal for demanding commercial applications and ensures long-lasting performance in harsh conditions.

Polished Finish & Enhanced Durability

The fittings feature a premium polished surface, contributing not just to their aesthetics but also to their resistance against oxidation and wear. Combined with galvanized treatment, the fittings are designed to withstand rigorous usage, maintaining reliability and structural integrity over time.

Wide Availability in India

As a major Indian dealer, manufacturer, exporter, and supplier, we maintain a robust inventory of standard-sized Copper Nickel 90-10 forged fittings. Our distribution network spans both domestic and international markets, ensuring prompt delivery and consistent product quality.

FAQs of Copper Nickel 90-10 Forged Fittings:

Q: How are Copper Nickel 90-10 Forged Fittings manufactured?

A: Copper Nickel 90-10 forged fittings are produced by forging a mixture composed of 90% copper and 10% nickel under high pressure. After shaping, the fittings are polished and treated with a galvanized finish to enhance both durability and appearance in line with ASTM standards.Q: What are the main benefits of using Copper Nickel 90-10 forged fittings?

A: These fittings offer excellent corrosion resistance, especially in marine and industrial settings. The polished and galvanized surface increases their lifespan, and the strong mechanical properties of the copper-nickel alloy provide superior durability and reliability.Q: When should Copper Nickel 90-10 forged fittings be used?

A: They are recommended for commercial projects where resistance to corrosion and structural strength are critical, such as in marine, chemical processing, and heavy industrial applications. Their robust surface treatment also makes them ideal for demanding environments.Q: Where are these Copper Nickel forged fittings typically installed?

A: These fittings are mainly used in commercial environments, including shipbuilding, offshore oil and gas platforms, chemical refineries, and other industrial installations where strong and corrosion-resistant piping components are necessary.Q: What is the usage process for Copper Nickel 90-10 forged fittings?

A: The fittings are installed by connecting them to pipelines according to standard engineering practices. Their standard sizes allow compatibility with a variety of pipe systems, making installation straightforward for commercial and industrial projects.Q: How does the galvanized treatment benefit these fittings?

A: The galvanized surface treatment provides an additional protective layer against environmental factors. This process significantly improves resistance to oxidation and extends the life of the fittings in harsh commercial environments.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें