Call : 08071793897

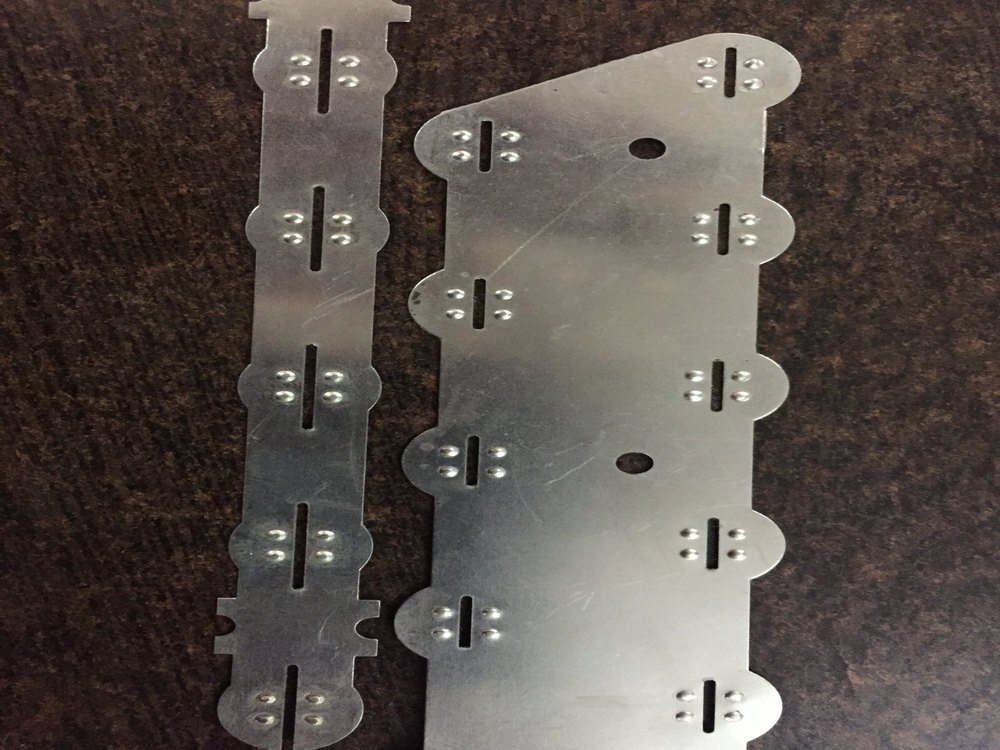

Nickel sheet

2000 आईएनआर/Kilograms

उत्पाद विवरण:

- प्रॉडक्ट टाइप

- शेप

- कठोरता Hard

- ग्रेड ≥99.6

- रंग Silver

- अधिक देखने के लिए क्लिक करें

X

मूल्य और मात्रा

- 100

उत्पाद की विशेषताएं

- ≥99.6

- Silver

- Hard

व्यापार सूचना

- प्रति महीने

- दिन

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें