Price 2100.0 आईएनआर/ Kilograms

MOQ : 100 Kilograms

Specification

- प्रॉडक्ट टाइप

- शेप

- दीर्घीकरण

- 15-35%

- स्ट्रेंथ

- High strength

- कठोरता

- Hard

- प्रतिरोध

- Low electrical resistance

- ग्रेड

- Ni200

- मेल्टिंग रेंज

- 1435 - 1455°C

- घनत्व

- ग्राम प्रति घन सेंटीमीटर (g/cm3)

- रासायनिक संरचना

- Nickel 99.96%

- एप्लीकेशन

- रंग

- Silver

- Width

- 0.15 mm - 3 mm (customized)

- Corrosion Resistance

- Excellent

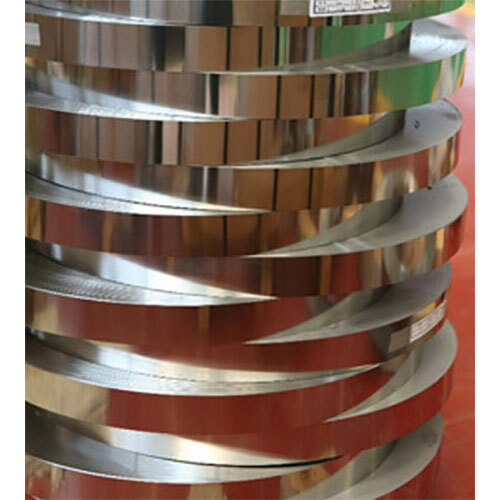

- Surface Finish

- Bright/Smooth

- Thickness

- 0.1 mm - 0.3 mm

- Packaging Type

- Coil/Roll

- Standard

- ASTM B162

- Operating Temperature Range

- -60°C to +300°C

- Width Tolerance

- ±0.05 mm

Trade Information

- Minimum Order Quantity

- 100 Kilograms

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- दिन

About

Nickel strip battery weldingconnects battery cells together by spot welding thin nickel or nickel-plated strips to them, forming a series or parallel battery pack.These strips offer low electrical resistance, high tensile strength, and excellent corrosion resistance, ensuring efficient and durable connections with minimal energy loss.They are popular because they are easy to solder or spot weld and dont puncture the batterys protective film.Common uses include manufacturing and repairing high-power battery packs for laptops, power tools, and electric vehicles.

- A component:Its a thin strip of pure nickel or, more commonly, nickel-plated steel.

- A process:The process of using this strip to create robust, low-resistance electrical connections between battery cells.

-

Provides excellent, efficient power transfer between cells with minimal resistance.

-

Offers high tensile strength, ensuring long-lasting and strong connections.

-

Protects against degradation and maintains connection integrity over time.

-

The material is designed to be easily spot welded or soldered to battery terminals.

High-Performance for Battery Welding

Engineered to meet the rigorous demands of battery welding and construction tasks, our nickel strip offers precision, stability, and outstanding electrical conductivity. The customizable width and thickness allow for versatile use, while the excellent elongation (15-35%) and hardness support robust, long-lasting welds. Its resistance to corrosion and high temperatures ensures reliability in both standard and extreme operating environments.

Quality Assurance and Standards

Every nickel strip we offer adheres to ASTM B162 specifications, guaranteeing consistency in chemical composition, mechanical properties, and dimensional accuracy. Our manufacturing processes prioritize the use of premium grade Ni200 nickel with 99.96% purity, meeting industrial requirements for high performance, corrosion resistance, and low electrical resistance. We supply to manufacturers, wholesalers, and traders across India, ensuring dependable service and product quality.

FAQs of Nickel Strip Battery Welding:

Q: How is this nickel strip utilized in battery welding?

A: The nickel strip acts as a conductive link between battery cells, enabling efficient electrical flow during assembly. Its high strength and low electrical resistance ensure durable connections and minimize energy loss.Q: What standards and specifications does your nickel strip follow?

A: Our nickel strip conforms to ASTM B162 and utilizes Ni200 grade nickel with a purity of 99.96%. Each strip is produced with stringent dimensional tolerances and high mechanical strength to ensure quality and performance.Q: When should I choose a width or thickness customization?

A: Customizable dimensions allow for precise matching to your specific battery application or assembly requirements. Choose the ideal width and thickness based on your cell size, current load, and mechanical fit for optimal welding results.Q: Where can your nickel strips be sourced in India?

A: We supply nickel strips to manufacturers, dealers, distributors, and wholesalers across India. संपर्क करें directly for tailored solutions and prompt delivery to your location.Q: What is the process for producing these high-strength nickel strips?

A: Our strips are processed through advanced rolling and annealing techniques, ensuring a bright/smooth surface finish, maintained purity, and uniform mechanical properties. Packaging is available in coil or roll form for convenience.Q: How does the corrosion resistance benefit battery welding applications?

A: Excellent corrosion resistance ensures long-lasting connections between cells, reducing the risk of degradation and maintaining electrical performance even in challenging operating environments.Q: What are the key advantages of your nickel strip in battery assembly?

A: Key benefits include customizable size, high electrical conductivity, superior corrosion resistance, elevated tensile strength, and reliable performance across a wide temperature range. These features streamline production and extend battery lifespan.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in निकल पट्टियाँ Category

निकेल स्ट्रिप्स

मूल्य या मूल्य सीमा : आईएनआर

न्यूनतम आदेश मात्रा : 100

मूल्य की इकाई : किलोग्राम/किलोग्राम

कठोरता : 110 HV

माप की इकाई : किलोग्राम/किलोग्राम

ग्रेड : औद्योगिक

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें