Price 2200.0 आईएनआर/ Kilograms

MOQ : 10 Kilograms

Specification

- प्रोडक्ट का नाम

- शेप

- सतह

- Polishing

- एप्लीकेशन

- रंग

- Silver

Trade Information

- Minimum Order Quantity

- 10 Kilograms

- आपूर्ति की क्षमता

- प्रति सप्ताह

- डिलीवरी का समय

- दिन

About

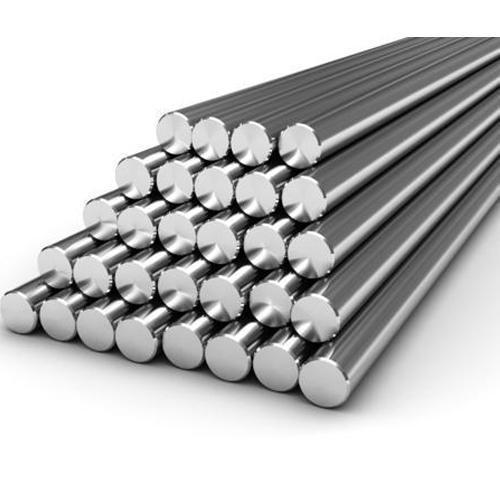

Titanium Grade 9 (Ti-3Al-2.5V) round bar is a medium-strength alloy offering an excellent balance of strength, corrosion resistance, and cold formability. With a composition of approximately 3% aluminum and 2.5% vanadium, it is significantly stronger than commercially pure titanium but more easily worked and welded than the higher-strength Grade 5. This combination of properties makes it ideal for applications requiring good strength-to-weight ratio and resilience in corrosive environments. It is widely used in aerospace for hydraulic tubing, in marine and chemical processing for corrosion-resistant components, and in high-performance sporting goods like bicycle frames. It maintains excellent properties even at elevated temperatures. Grade 9 Titanium Ti-3Al-2.5V is a versatile titanium alloy widely used in sporting equipment and aerospace titanium tubing due to its excellent strength-to-weight ratio, corrosion resistance, and superior weldability

Superior Performance in Construction

Titanium Grade 9 round bars are highly valued in the construction industry for their robust yet lightweight composition, providing structural strength without unnecessary bulk. Their resilience to harsh weather conditions and high resistance to corrosion make them suitable for both indoor and outdoor architectural applications, ensuring long-lasting reliability in construction projects.

Refined Surface Finish for Enhanced Functionality

Every Titanium Grade 9 round bar undergoes a meticulous polishing process, resulting in a sleek, silver appearance. This polished surface not only enhances aesthetic appeal but also improves material performance by reducing the likelihood of surface defects and offering ease of cleaning, making it an excellent choice for visible structural elements or architectural designs demanding visual sophistication.

FAQs of Titanium grade 9 round bar:

Q: How is the Titanium Grade 9 round bar manufactured for construction applications?

A: The Titanium Grade 9 round bar is produced using advanced metallurgical processes that involve melting, forming, and precision polishing. The result is a material that offers an optimal balance between strength, durability, and surface smoothness, making it well-suited for use in construction environments.Q: What are the main advantages of using a polished Titanium Grade 9 round bar?

A: Polished Titanium Grade 9 round bars feature a corrosion-resistant and easy-to-clean surface, which extends longevity and maintains their silver luster. Their superior mechanical properties make them an excellent choice for demanding applications in construction, ensuring reliability over extended periods.Q: When should Titanium Grade 9 round bars be chosen over other materials in construction?

A: These round bars are particularly advantageous when high strength, low weight, and corrosion resistance are requiredsuch as in high-rise structures, bridges, or architectural accents exposed to the elements. Their refined appearance also makes them ideal for visible installations.Q: Where can I purchase Titanium Grade 9 round bars in India?

A: Titanium Grade 9 round bars are available throughout India from a comprehensive network that includes dealers, distributors, exporters, importers, manufacturers, suppliers, traders, and wholesalers. This extensive supply chain ensures accessibility for both large and small construction projects.Q: What is the process involved in polishing Titanium Grade 9 round bars?

A: The bars undergo a multi-stage polishing process that removes surface imperfections and enhances the natural silver finish. This not only imparts a visually striking appearance but also strengthens the integrity of the surface, contributing to overall material performance.Q: How does the shape of the round bar benefit its usage in construction?

A: The round shape of the Titanium Grade 9 bar provides uniform strength and facilitates easy handling during installation. It is particularly useful in frameworks, supports, or connections where directional loads are involved, improving overall build quality.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें