Call: 08071793897

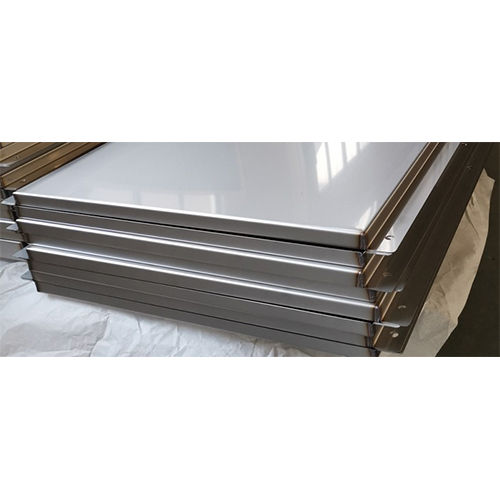

Stainless steel Sheets

Price 290.0 INR/ Kilograms

MOQ : 100 Kilograms

Stainless steel Sheets Specification

- Product Name

- Steel Products

- Steel Type

- Stainless Steel

- Grade

- Industrial

- Shape

- Plate

- Surface

- Galvanized

- Application

- Construction

- Color

- Silver

Stainless steel Sheets Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 1000 Kilograms Per Day

- Delivery Time

- 5 Days

- Main Domestic Market

- All India

About Stainless steel Sheets

Stainless steel sheets are flat, thin metal materials made from a steel alloy with a minimum of 10.5% chromium. The chromium content gives them exceptional corrosion and rust resistance by forming a self-healing, protective oxide layer. Available in various grades like 304 and 316, and different finishes from polished to brushed, they offer durability, strength, and a hygienic, aesthetic surface. Uses range from kitchen appliances and architectural cladding to marine and medical equipment.SS sheet" is a thin, flat piece of stainless steel, a corrosion-resistant metal alloy. They are used in a wide variety of applications due to their strength, durability, and versatility, with common uses in construction, kitchenware, automotive parts, and medical devices.

-

Stainless steel is an iron alloy that contains a minimum of 10.5% chromium, which prevents rust and corrosion. Other elements like nickel, molybdenum, and carbon are often added to provide unique properties.

-

SS sheets come in various grades, with common ones including 304 and 316, which have different compositions and characteristics to suit different needs.

-

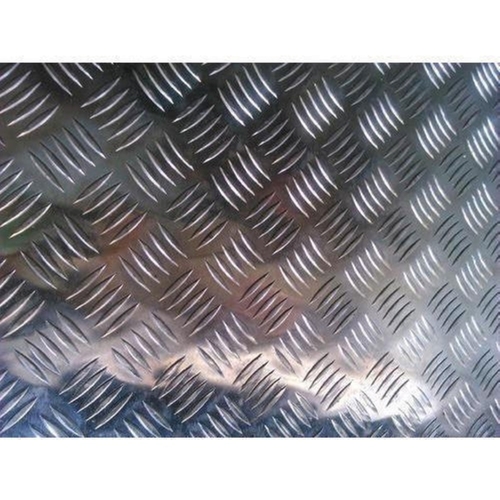

They can have different surface finishes, such as brushed, polished, or matte, depending on the desired appearance and application.

-

They are available in various thicknesses and sizes, from thin sheets to thicker plates, and can be supplied in different forms like cold-rolled, hot-rolled, or perforated.

- Construction: Used for structural elements, roofing, and cladding.

- Kitchenware: Common in appliances, cutlery, and cooking utensils.

- Automotive: Used in vehicle parts and for exterior and interior components.

- Medical: Utilized for surgical equipment, implants, and other medical devices due to its hygienic and non-reactive properties.

- Marine: Employed in boat fittings and hardware because of its resistance to salt and moisture.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry