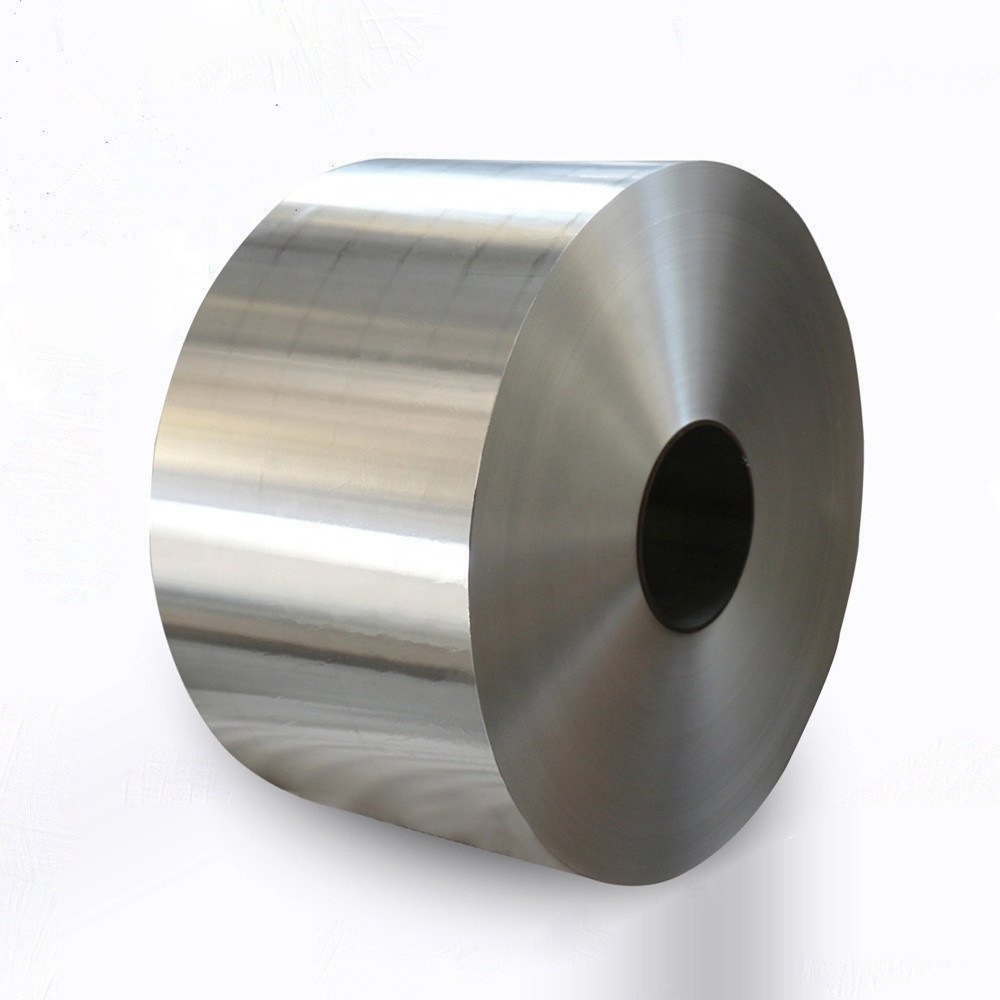

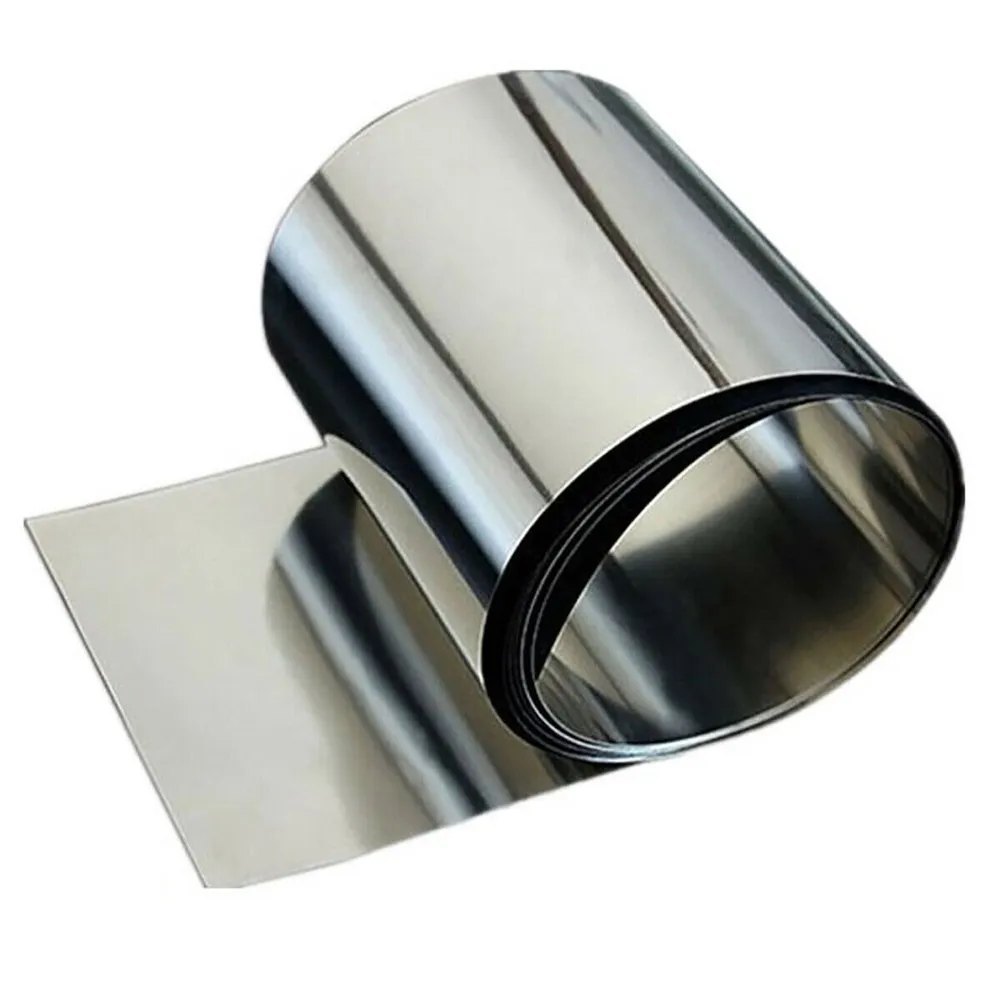

Stainless Steel Slitting Coil

Price 250.0 INR/ Kilograms

Stainless Steel Slitting Coil Specification

- Usage

- Industrial

- Material

- Stainless Steel

- Size

- Standard

- Grade

- SS304

- Product Type

- Stainless Steel Slitting Coil

- Coil Thickness

- 0.5-10 Millimeter (mm)

- Color

- Silver

- Application

- Industrial

Stainless Steel Slitting Coil Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Supply Ability

- 1000 Kilograms Per Day

- Delivery Time

- 7 Days

About Stainless Steel Slitting Coil

A stainless steel slitting coil is a large roll of stainless steel that has been precisely cut lengthwise into narrower strips. This process, done with rotary blades, creates smaller, customized coils for specific manufacturing needs. The resulting slit coil maintains the original stainless steels durability, corrosion resistance, and specific grade properties (e.g., 304, 316). It is widely used for producing components in the automotive, appliance, construction, and electronics industries where precise width and tight tolerances are critical. Stainless steel coils are flat strips of stainless steel that have been wound into a coil shape. They are manufactured from stainless steel sheets or plates and can be us- Corrosion Resistance: Durable and resistant to rust.

- Customizable: Available in various grades, widths, thicknesses, and surface finishes.

- Precision: Provides consistent, high-quality strips with minimal burr, which is essential for manufacturing processes like stamping and forming.

Superior Material Quality

Manufactured from SS304, this stainless steel slitting coil delivers outstanding durability and resistance to oxidation. Widely regarded for its reliability, SS304 is suited for demanding industrial environments, ensuring prolonged lifespan and minimal maintenance.

Precision Slitting for Various Uses

Available in coil thicknesses from 0.5 to 10 mm, these slitting coils can be customized to specific width requirements. They are essential for fabrication processes such as automotive parts, construction reinforcements, and appliance manufacturing.

FAQs of Stainless Steel Slitting Coil:

Q: How are stainless steel slitting coils typically used in industrial applications?

A: These slitting coils are widely used in manufacturing processes including stamping, forming, and cutting for industries such as construction, automotive, and electrical. Their versatility allows for use in creating components, supports, and enclosures.Q: What is the process involved in slitting stainless steel coils?

A: The process involves unrolling the master coil, passing it through rotary knives to achieve desired strip widths, and then recoiling the slit strips. This ensures precise dimensions and smooth edges suited for further processing.Q: When should I choose SS304 grade for slitting coil applications?

A: SS304 is chosen when excellent corrosion resistance, formability, and strength are required. It is ideal for both indoor and outdoor industrial uses, especially in environments exposed to moisture or chemicals.Q: Where can I source stainless steel slitting coils in India?

A: These coils are readily available through a network of dealers, distributors, exporters, importers, manufacturers, suppliers, traders, and wholesalers across India. Specialized suppliers cater to industrial requirements with quality assurance.Q: What are the main benefits of using this stainless steel slitting coil?

A: Key benefits include enhanced durability, resistance to rust and stains, consistent quality, and adaptability to various industrial processes. This reduces downtime and improves product longevity.Q: How can standard size and thickness options benefit industrial users?

A: Standardized thicknesses (0.510 mm) and sizes simplify inventory management and ensure compatibility with automated machinery, increasing operational efficiency and reducing waste in production lines.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metal Coil Category

202 Stainless Steel Coil

Price 170.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Usage : Industrial

Material : Stainless Steel

Product Type : 202 Stainless Steel Coil

Color : Silver

Inconel 718 Strip Coil

Price 4500.0 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Usage : Industrial

Material : Other

Product Type : Inconel 718 Strip Coil

Color : Silver

316L Stainless Steel Coil

Price 400.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Usage : Industrial

Material : Stainless Steel

Product Type : 316L Stainless Steel Coil

Color : Silver

304 Stainless Steel Coil

Price 250.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Usage : Industrial

Material : Stainless Steel

Product Type : 304 Stainless Steel Coil

Color : Silver

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry