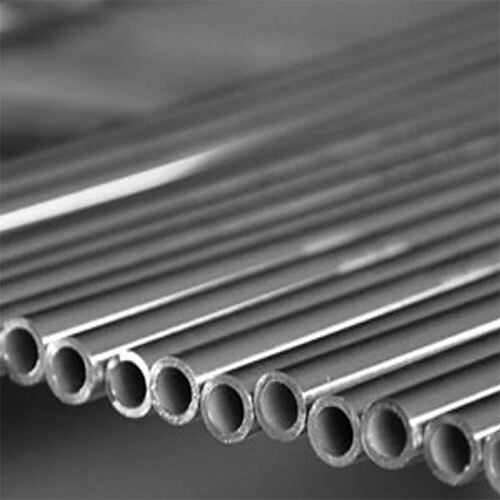

316L Stainless Steel Pipe

Price 450.0 INR/ Kilograms

316L Stainless Steel Pipe Specification

- Usage

- Industrial

- Diameter

- 20-400 Millimeter (mm)

- Material Grade

- A

- Material

- Stainless Steel

- Shape

- Round

- Application

- Industrial

- Product Type

- 316L Stainless Steel Pipe

- Length

- 3 Meter (m)

316L Stainless Steel Pipe Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Supply Ability

- 1000 Kilograms Per Week

- Delivery Time

- 5 Days

About 316L Stainless Steel Pipe

- A low-carbon austenitic stainless steel with chromium, nickel, and molybdenum.

- Excellent resistance to pitting, crevice corrosion, and chloride ions, especially in marine or acidic environments.

- Superior weldability compared to 316 due to the low carbon content, which reduces carbide precipitation and the risk of intergranular corrosion after welding.

- Commonly used in industries requiring high corrosion resistance, such as chemical processing, marine, pharmaceutical, and food production.

- Durable, high strength, and can be fabricated easily.They can be hardened by cold working, but not by heat treatment.

Premium Quality and Versatility

These 316L stainless steel pipes are recognized for their exceptional resistance to corrosion and chemical exposure, making them suitable for diverse industrial applications. Their round shape and broad diameter range allow for flexible integration into piping systems, while the consistent 3-meter length supports easy installation and maintenance.

Reliable Supply Network

As a trusted product among dealers, manufacturers, and suppliers in India, these stainless steel pipes are readily available through multiple distribution channels. Whether you require a single length or bulk orders, the extensive network ensures prompt delivery for projects of any scale.

FAQs of 316L Stainless Steel Pipe:

Q: How are 316L stainless steel pipes typically used in industrial settings?

A: 316L stainless steel pipes are predominantly used in industries requiring high corrosion resistance, such as chemical processing, food production, pharmaceuticals, and water treatment plants. Their ability to withstand harsh environments makes them suitable for transporting fluids and gases safely.Q: What is the manufacturing process for these stainless steel pipes?

A: The pipes are produced by forming and welding premium 316L stainless steel, followed by precision finishing techniques to ensure roundness, consistent wall thickness, and a smooth internal surface. Each pipe is tested for grade A quality to match industrial standards.Q: When should 316L stainless steel pipes be chosen over other materials?

A: Choose 316L stainless steel pipes when your application demands superior corrosion resistance, particularly in environments exposed to acids, chlorides, or high moisture. Their longevity and minimal maintenance requirements offer major advantages over conventional pipes.Q: Where can I source these stainless steel pipes in India?

A: These pipes are widely available across India through authorized dealers, distributors, suppliers, manufacturers, traders, and wholesalers. Many exporters and importers also facilitate international shipping to suit different supply chain needs.Q: What benefits do 316L grade pipes offer for industrial applications?

A: 316L grade stainless steel pipes provide excellent resilience against corrosion, high temperatures, and mechanical stress. They ensure reliable performance, safety, and reduced downtime, making them a preferred choice for demanding industrial processes.Q: How does the pipes round shape and diameter range contribute to its usage?

A: The round shape allows for even fluid distribution and minimizes resistance, while the wide diameter range (20400 mm) supports various flow rates and system requirements, enhancing versatility in complex industrial operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Pipes And Tubes Category

Stainless Steel Seamless Pipes

Price 450.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Material : Stainless Steel

Section Shape : Round

Application : Industrial

Usage : Industrial

SS316L Stainless Steel Square Pipe

Price 400.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Material : Stainless Steel

Section Shape : Square

Application : Industrial

Usage : Industrial

310S Stainless Steel Pipes

Price 875.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Material : Stainless Steel

Section Shape : Round

Application : Industrial

Usage : Industrial

316 Stainless Steel Pipe

Price 450.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Material : Stainless Steel

Section Shape : Round

Application : Industrial

Usage : Industrial

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry