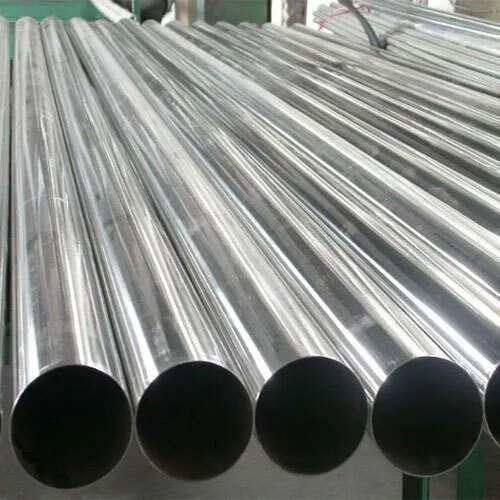

Stainless Steel Seamless Pipes

Price 450.0 INR/ Kilograms

MOQ : 100 Kilograms

Stainless Steel Seamless Pipes Specification

- Application

- Industrial

- Material

- Stainless Steel

- Material Grade

- A

- Surface Finish

- Polished

- Shape

- Round

- Product Type

- Seamless Steel Pipes

- Usage

- Industrial

- Section Shape

- Round

- Thickness

- 5-15 Millimeter (mm)

- Size

- 2 Inch

- Length

- 3 Meter (m)

Stainless Steel Seamless Pipes Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Supply Ability

- 1000 Kilograms Per Day

- Delivery Time

- 7 Days

About Stainless Steel Seamless Pipes

Stainless steel seamless pipes arehigh-quality tubes produced from a solid stainless steel billet without any welding. This manufacturing process involves piercing the heated billet and then elongating it to the required size, resulting in a uniform, joint-free structure. The absence of welded seams eliminates weak points, giving seamless pipes superior strength, durability, and resistance to corrosion and mechanical stress. They are a reliable choice for high-pressure, high-temperature, and corrosive applications across industries like oil and gas, chemical processing, pharmaceuticals, and power generation.Versatile Industrial Applications

These stainless steel seamless pipes serve a variety of industrial applications such as chemical processing, food manufacturing, and heavy machinery construction. Their polished finish and robust structure ensure longevity and high performance, even in challenging environments. The uniform thickness and smooth inner surface also promote efficient fluid transfer and minimal pressure loss, making them a preferred choice for multiple sectors.

Quality and Reliability Guaranteed

With strict adherence to Material Grade A, our stainless steel pipes undergo thorough inspection throughout the manufacturing process. Sourced and supplied by trusted distributors, exporters, and manufacturers, each pipe upholds standards of strength, corrosion resistance, and dimensional accuracy. These pipes are engineered to withstand high pressure and temperatures, providing long-lasting service and cost-effective solutions for industrial users.

FAQs of Stainless Steel Seamless Pipes:

Q: How are stainless steel seamless pipes manufactured for industrial use?

A: Stainless steel seamless pipes are produced through extrusion and cold drawing processes, ensuring a continuous, weld-free construction. This method enhances the pipes strength, uniformity, and resistance to corrosion, making it ideal for demanding industrial applications.Q: What are the benefits of using polished stainless steel seamless pipes?

A: The polished surface finish not only provides a visually appealing appearance but also improves corrosion resistance and reduces the risk of material buildup inside the pipe, ensuring efficient fluid flow.Q: When should I choose seamless pipes over welded pipes for my industrial project?

A: Seamless pipes are preferred in high-pressure and high-temperature environments where maximum strength and leak-proof performance are essential. Theyre ideal when a flawless internal surface and superior durability are required.Q: Where can these stainless steel seamless pipes be sourced from in India?

A: These pipes can be obtained from established dealers, distributors, manufacturers, exporters, importers, suppliers, traders, and wholesalers throughout India, ensuring broad availability for various industrial projects.Q: What is the typical usage of 2-inch round stainless steel seamless pipes?

A: These pipes are commonly used in process piping, transport of chemicals and gases, construction frameworks, and other industrial systems that demand strength and corrosion resistance.Q: How does the thickness range of 5-15 mm benefit industrial operations?

A: A thickness between 5 and 15 mm provides enhanced mechanical strength, supports higher pressure ratings, and offers increased resistance to physical impact and wear, making these pipes suitable for critical industrial processes.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Stainless Steel Pipes And Tubes Category

304 Stainless Steel Pipes

Price 250.0 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Shape : Round

Application : Industrial

Material Grade : A

Material : Stainless Steel

Stainless Steel Polished Pipe

Price 350.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Shape : Round

Application : Industrial

Material Grade : A

Material : Stainless Steel

Aluminium Alloys Tube

Price 850.0 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Shape : Round

Application : Industrial

Material Grade : A

Material : Aluminium

Seamless Stainless Steel Tube

Price 400.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Shape : Round

Application : Industrial

Material Grade : A

Material : Stainless Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry