Price 280.0 आईएनआर/ Kilograms

MOQ : 100 Kilograms

Specification

- सतह का उपचार

- उपयोग

- Industrial

- मटेरियल

- साइज

- Standard

- प्रॉडक्ट टाइप

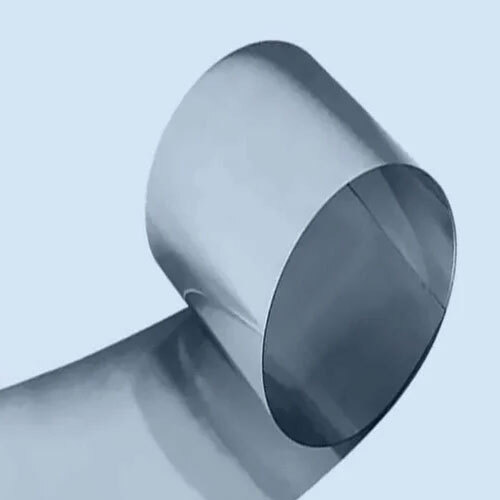

- 321 Stainless Steel Coils

- रंग

- Silver

- चौड़ाई

- मिलीमीटर (mm)

- एप्लीकेशन

- Construction

Trade Information

- Minimum Order Quantity

- 100 Kilograms

- आपूर्ति की क्षमता

- प्रति दिन

- डिलीवरी का समय

- दिन

About

321 stainless steel coils area titanium-stabilized austenitic stainless steel known for its exceptional high-temperature resistance and resistance to intergranular corrosion. It is essentially a version of grade 304 stainless steel with titanium added to prevent carbide precipitation during welding and when used in the 427816C temperature range.This grade offers higher creep and stress rupture properties compared to 304, along with good corrosion resistance and toughness. Its characteristics make it ideal for high-temperature applications like aerospace exhaust manifolds, heat exchangers, and chemical processing equipment. It is also easily formed and welded.It is ideal forheat exchangers, pressure vessels, and storage tanks. Thermal Equipment: Boilers, heat exchangers, and furnace parts often utilize 321 stainless steel because of its excellent resistance to heat and oxidation. It is commonly found in industrial heat-treating equipment

Versatile Applications in Construction

321 Stainless Steel Coils are engineered to meet the high standards of the construction industry. Their durability, formability, and excellent resistance to heat and corrosion make them a preferred choice for structural frameworks, cladding, and architectural elements. Their broad width range offers flexibility for diverse project needs.

Superior Polished Finish

Each coil features a polished surface treatment, enhancing both appearance and performance. The silver finish not only provides aesthetic value but also contributes to easy cleaning and reduced risk of surface contamination, crucial for industrial and construction environments.

Wide Distribution नेटवर्क

As a leading dealer, distributor, exporter, importer, manufacturer, supplier, trader, and wholesaler, we ensure seamless supply of 321 Stainless Steel Coils across India. Our robust logistic network guarantees timely delivery and personalized service for bulk orders and customized requirements.

FAQs of 321 Stainless Steel Coils:

Q: How are 321 Stainless Steel Coils typically used in construction applications?

A: These coils are commonly utilized for structural supports, wall cladding, roofing, and various architectural components due to their durability and resistance to high temperatures and corrosion.Q: What benefits does the polished finish of these coils offer in industrial settings?

A: A polished surface enhances visual appeal, increases resistance to surface corrosion, and facilitates easier cleaning, ensuring longevity and maintaining hygiene in industrial and construction environments.Q: Where can I source 321 Stainless Steel Coils in India?

A: You can obtain these coils across India through reliable dealers, distributors, exporters, importers, manufacturers, suppliers, traders, and wholesalers like us, ensuring quality and timely delivery.Q: What is the process behind manufacturing 321 Stainless Steel Coils?

A: The coils are produced by melting high-grade stainless steel, casting, hot rolling, cold rolling to required thickness and width, followed by surface polishing to achieve the desired finish.Q: When is it ideal to use 321 Stainless Steel Coils over other stainless steel grades?

A: These coils are recommended when applications require enhanced resistance to intergranular corrosion at high temperatures, such as in furnace parts or heat exchangers.Q: How do the size options accommodate different industrial needs?

A: With standard widths ranging from 200 to 2000 millimeters, these coils cater to a variety of project specifications, enabling efficient customization for different construction or industrial applications.Q: What are the main advantages of using 321 Stainless Steel material in coil form?

A: 321 Stainless Steel offers excellent stability against heat, strong resistance to corrosion, and retains mechanical properties at elevated temperatures, making it advantageous for demanding industrial uses.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें