Specification

- प्रॉडक्ट टाइप

- शेप

- कठोरता

- 110-150 HV

- ग्रेड

- Ni-200/201

- रासायनिक संरचना

- 99.5%

- एप्लीकेशन

- , , , ,

- रंग

- Silver

Trade Information

- एफओबी पोर्ट

- mumbai

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- दिन

- नमूना उपलब्ध

- No

- नमूना नीति

- पैकेजिंग का विवरण

- EXPORT PACKING

- मुख्य निर्यात बाजार

- , , , , , , , ,

- प्रमाणपत्र

- ISO

About

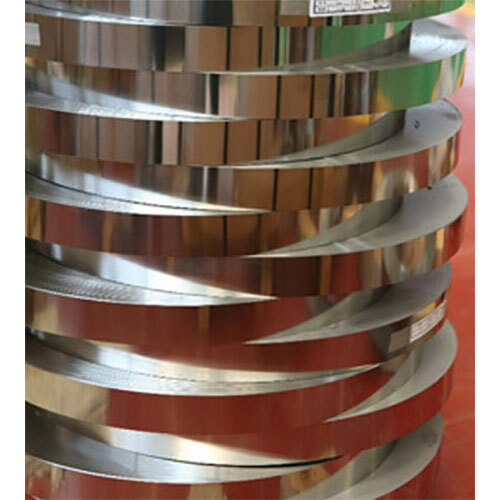

High-purity nickel strip, typically over 99.6% pure, is a conductor widely used in battery packs and electronics due to its excellent electrical and thermal conductivity. Its high conductivity ensures minimal resistance and efficient energy transfer within battery assemblies.

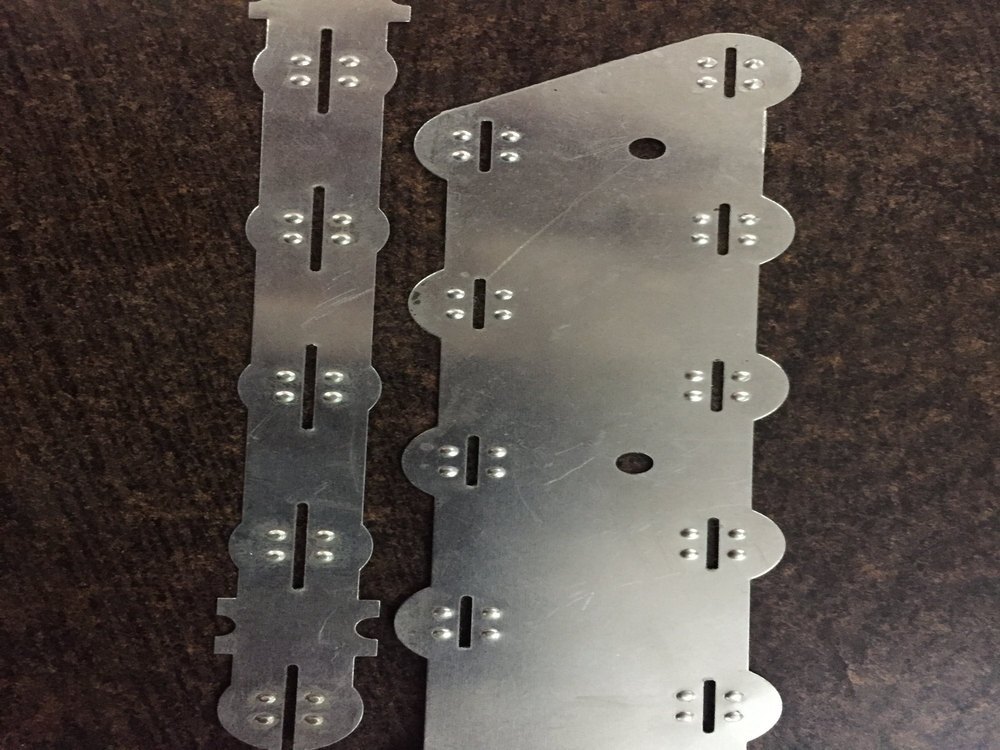

Known for strong corrosion resistance, it provides reliable connections that prolong the lifespan of batteries and electronic components. This material also offers great mechanical strength, formability, and weldability, allowing for robust and dependable connections, particularly for spot welding individual battery cells.

Exceptional Chemical Purity

Maintaining a chemical composition of 99.5%, our nickel strip provides outstanding corrosion resistance and electrical conductivity. This high purity level is essential in demanding sectors like nuclear and electronics, where even trace impurities can impact performance.

Versatile Industrial Applications

The Ni-200/201 nickel strips are widely utilized in key industries including steel manufacturing, chemical processing, petroleum refining, and electronic component production. Their combination of mechanical strength and chemical inertness underpins superior performance in both conventional and advanced industrial settings.

Reliable Supply and Distribution नेटवर्क

Operating as a dealer, exporter, importer, and supplier based in India, we ensure prompt delivery and comprehensive after-sales support. Our extensive network empowers clients across various sectors to access top-grade nickel strips for ongoing and new projects.

FAQs of High Purity Nickel Strip:

Q: How are High Purity Nickel Strips manufactured and processed?

A: High Purity Nickel Strips with Grade Ni-200/201 are produced through advanced refining processes followed by rolling into the desired stripe shape. Quality controls during manufacturing ensure a chemical purity of 99.5% and a consistent hardness of 110-150 HV.Q: What are the main industrial applications of this nickel strip?

A: These nickel strips serve crucial roles in steel making, nuclear power plants, petroleum refineries, chemical processing units, and electronic manufacturing due to their high purity and excellent mechanical properties.Q: When should I choose Ni-200/201 grade nickel strip over other grades?

A: Ni-200/201 grade is preferred when exceptional purity, corrosion resistance, and electrical conductivity are requiredas in nuclear, electronic, and chemical industry applications where material integrity is non-negotiable.Q: Where can I source High Purity Nickel Strip in India?

A: You can obtain these nickel strips from reputable dealers, distributors, exporters, importers, manufacturers, and suppliers situated across India. We offer nationwide coverage with reliable stock and timely deliveries.Q: What is the standard hardness and why is it important?

A: The strip exhibits a hardness range of 110-150 HV, balancing flexibility with structural stability for high-performance use in fabrication, assembly, and demanding operating environments.Q: How is this product beneficial for use in nuclear and chemical industries?

A: Its high chemical stability, purity, and resistance to corrosion make it ideal for nuclear and chemical sectors, where maintaining safety and operational integrity is paramount.Q: What advantages do you offer as a trader and wholesaler of nickel strips?

A: As a leading trader and wholesaler, we provide competitive pricing, consistent quality, bulk order capability, and expert technical support, ensuring value and reliability for your production needs.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in निकल पट्टियाँ Category

निकेल स्ट्रिप्स

माप की इकाई : किलोग्राम/किलोग्राम

न्यूनतम आदेश मात्रा : 100

मूल्य या मूल्य सीमा : आईएनआर

कठोरता : 110 HV

प्रॉडक्ट टाइप : निकेल

मूल्य की इकाई : किलोग्राम/किलोग्राम

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें