Specification

- मटेरियल

- टाइप करें

- कनेक्शन

- Male/Female Threaded, Socket Weld

- स्टैण्डर्ड

- फिनिशिंग

- सतह का उपचार

- ग्रेड

- Nickel 200

- व्यास

- मिलीमीटर (mm)

- मोटाई

- माइक्रोमीटर (um)

- Applications

- Oil & Gas, Chemical Processing, Petrochemical, Power Generation, Marine

- Corrosion Resistance

- Excellent, suitable for chemical and marine environments

- Pressure Rating

- Class 2000, 3000, 6000, 9000 LBS

- Tolerance

- As per ASTM standards

- Temperature Range

- Up to 600°C

- Density

- 8.9 g/cm³

- Hardness

- Rockwell B65 max

- End Type

- BSP, NPT, Socket Weld

Trade Information

- Minimum Order Quantity

- 100 Kilograms

- भुगतान की शर्तें

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- दिन

- नमूना उपलब्ध

- No

- नमूना नीति

- मुख्य घरेलू बाज़ार

About

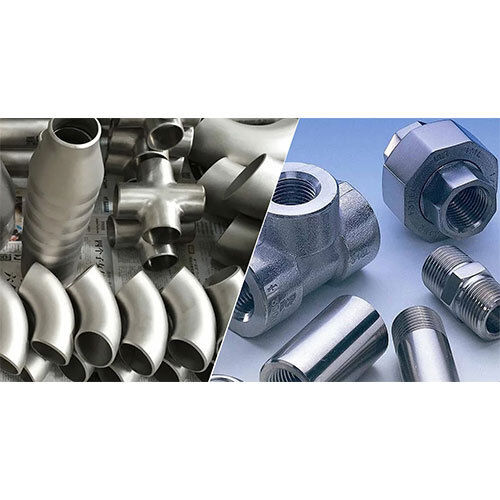

Nickel 200 Forged Threaded Cap, powdered to maximize the reactive surface area, shows a significant chemical activity, but larger pieces are slow to react with air under standard conditions because an oxide layer forms on the surface and prevents further corrosion . Nickel 201 Forged Threaded Fittings has excellent resistance to anhydrous hydrofluoric acid even at elevated temperatures. An important reason for its success is that the corrosion product of Nickel 201 Forged Threaded Elbow, such as nickel chloride, has a relatively low solubility in this range of concentration. Because of this reason, Nickel 200 Forged Threaded Tee should be used only with caution when solutions are at high velocity.Nickel 200 Forged Threaded Cross is a chemical element, where it is a silvery-white lustrous metal with a slight golden tinge.

High-Performance Corrosion Resistance

Nickel 200 Forged Fittings offer outstanding resistance to a wide array of corrosive substances, making them ideal for applications in chemical and marine environments. Their robust construction helps minimize contamination and ensures long-term reliability even under harsh operating conditions. They are particularly valued in processes where integrity and low maintenance are critical.

Versatile Connection and Shape Options

Available in BSP, NPT, and Socket Weld end types, these fittings accommodate a variety of piping systems. The diverse shapeselbows, tees, couplings, unions, caps, and plugsallow for flexible design and installation. Threaded and socket weld connections, as well as customizable male/female threads, provide secure and leak-free assembly for any project specifications.

FAQs of Nickel 200 Forged Fittings:

Q: How are Nickel 200 Forged Fittings manufactured and what standards do they follow?

A: Nickel 200 Forged Fittings are produced by hot forging premium Nickel 200 billets using advanced techniques. They adhere to ASTM manufacturing tolerances and hardness standards to ensure high mechanical strength, durability, and dimensional accuracy. Their hardness does not exceed Rockwell B65, guaranteeing machinability and toughness.Q: What makes Nickel 200 Forged Fittings suitable for chemical processing and marine applications?

A: Their excellent resistance to a broad spectrum of corrosive environments, coupled with high temperaturesup to 600Cmakes them particularly effective in chemical processing and marine installations. Nickel 200s purity and stability limit contamination and corrosion, ensuring prolonged service life and minimal maintenance.Q: When should Nickel 200 Forged Fittings be used instead of other materials?

A: Nickel 200 Forged Fittings are recommended when applications demand superior corrosion resistance, especially to alkalis and neutral salts, and require long-term durability at elevated temperatures. Typical environments include chemical plants, offshore platforms, and sites with aggressive media where standard fittings would fail prematurely.Q: Where can these fittings be utilized within an industrial setting?

A: Youll find Nickel 200 Forged Fittings deployed in oil & gas facilities, chemical processing plants, petrochemical complexes, marine equipment, and power generation systems. Their adaptability to different connection types and shapes makes them suitable for a wide range of piping networks where reliability is paramount.Q: What are the connection end options available for these fittings and how do you select the right one?

A: Nickel 200 Forged Fittings come with BSP, NPT, or Socket Weld ends, as well as male and female threaded options. The selection depends on your piping design, pressure requirements, and installation method; threaded connections suit quick assembly, while socket welds provide added strength for higher pressures.Q: How do users benefit from employing Nickel 200 Forged Fittings in their systems?

A: Users gain the advantage of extended equipment lifespan, reduced maintenance costs, and assurance of leak-free, robust connections. The fittings superior corrosion resistance ensures safer operation and minimizes downtime, contributing to overall efficiency and lower total cost of ownership in critical applications.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें