Price 2500.0 आईएनआर/ Kilograms

MOQ : 10 Kilograms

Specification

- प्रोडक्ट का नाम

- शेप

- सतह

- Polishing

- एप्लीकेशन

- रंग

- Silver

Trade Information

- Minimum Order Quantity

- 10 Kilograms

- आपूर्ति की क्षमता

- प्रति सप्ताह

- डिलीवरी का समय

- दिन

About

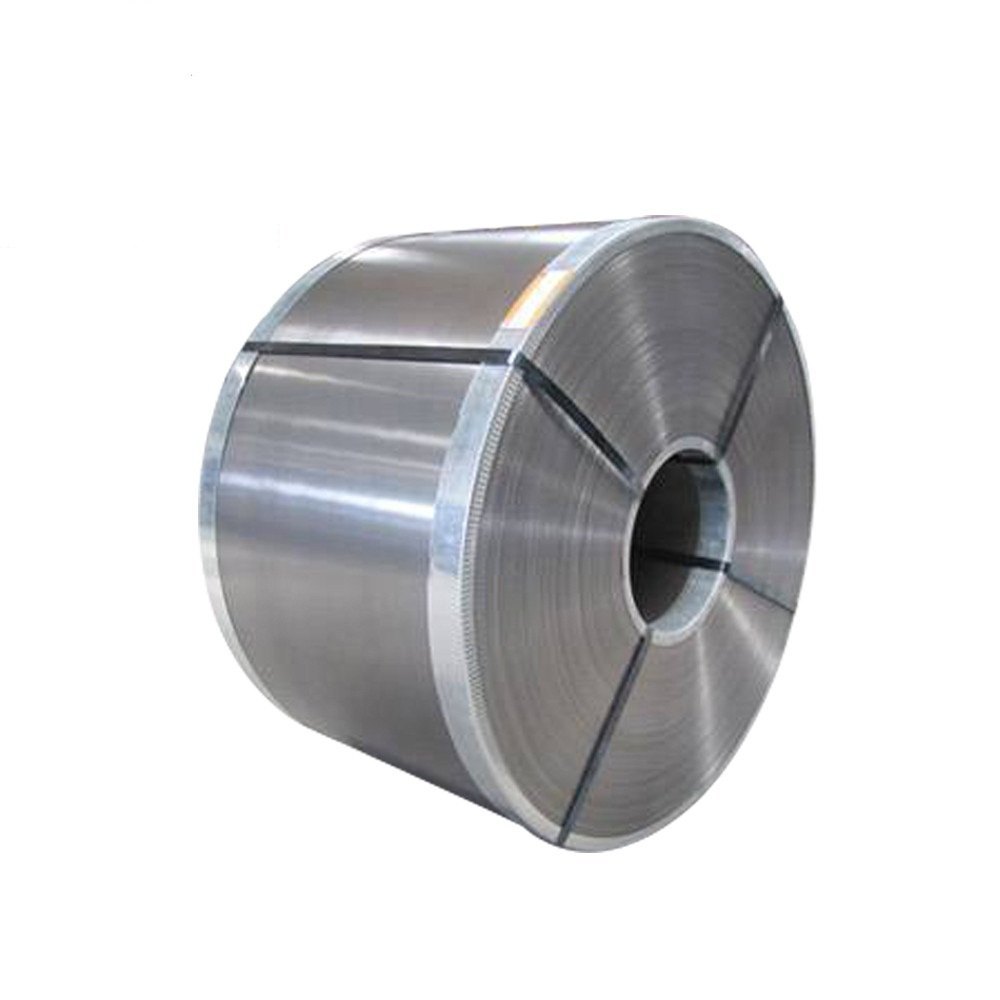

Nickel alloy coils are materials prized for their superior corrosion and heat resistance, high tensile strength, and exceptional mechanical properties. Composed of nickel combined with elements like chromium, molybdenum, and iron, they are highly versatile and durable. Applications are found across demanding industries such as chemical processing, aerospace, and oil and gas, where they are used for parts including heat exchangers, piping, and engine components. These coils are available in various grades, sizes, and finishes to suit specific performance requirements.Superior Performance and Customization

Made from high-grade nickel alloy, these coils are tailored to match specific construction demands. The customizable shape feature provides flexibility, accommodating diverse structural and design requirements. The polished silver surface delivers both visual appeal and practical protection.

Proudly Distributed Across India

Serving as a reliable dealer, distributor, exporter, importer, manufacturer, supplier, trader, and wholesaler, we ensure prompt delivery and broad availability of nickel alloy coils throughout India. Our expertise guarantees product authenticity and customer satisfaction at every stage.

FAQs of NICKEL ALLOY COIL:

Q: How is the nickel alloy coil used in construction projects?

A: Nickel alloy coils are commonly implemented in various construction tasks, such as building facades, structural reinforcements, and architectural accents. Thanks to their corrosion resistance and durability, they are ideal for environments exposed to harsh elements.Q: What benefits does the polished silver surface provide?

A: The polished silver surface enhances the coils appearance and provides a protective layer against corrosion and wear. This not only maintains the materials integrity but also adds a modern, clean finish suitable for both visible and concealed applications.Q: When should I consider using a nickel alloy coil over other materials?

A: Nickel alloy coils are recommended whenever exceptional strength, corrosion resistance, and longevity are required, particularly in construction settings exposed to moisture, chemicals, or high temperatures. Theyre preferred over conventional materials for projects demanding both resilience and aesthetics.Q: Where can I purchase or source nickel alloy coils in India?

A: Nickel alloy coils are available across India through a network of dealers, distributors, exporters, importers, manufacturers, suppliers, traders, and wholesalers. You can obtain them from authorized suppliers to ensure quality and reliable support.Q: What is the process for customizing the shape of a nickel alloy coil?

A: Customization involves understanding the project requirements and fabricating the coil to desired dimensions and specifications. Customers can provide detailed drawings or descriptions, and manufacturers will shape the coils accordingly to fit unique applications.Q: How does the manufacturing process ensure coil quality and durability?

A: The coils are produced using advanced metallurgy and precise quality control standards. Each coil undergoes surface polishing and rigorous inspections to ensure it meets industry criteria for strength, finish, and corrosion resistance.Q: What advantages does sourcing from a certified supplier in India offer?

A: Working with certified suppliers guarantees product authenticity, consistency, and adherence to international quality standards. It also offers better after-sales service, technical guidance, and reliable logistics for timely delivery across India.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें