Price 1100.0 आईएनआर/ Kilograms

MOQ : 10 Kilograms

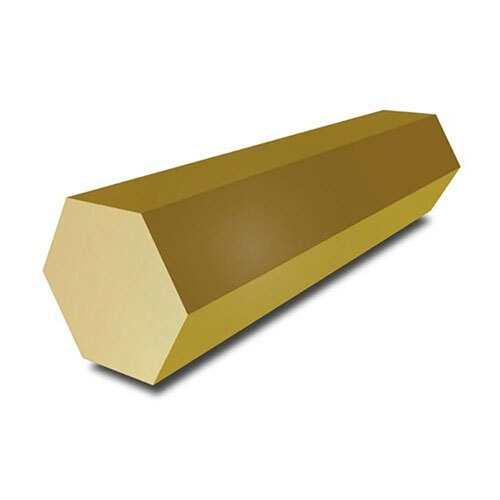

Specification

- व्यास

- मिलीमीटर (mm)

- शेप

- Round

- मटेरियल

- Phosphor Bronze

- टाइप करें

- Phosphor Bronze Rod

- एप्लीकेशन

- Industrial

- लम्बाई

- मीटर (m)

- सतह की फ़िनिश

- Polished

- उपयोग

- Construction

- ग्रेड

- C544

- सामग्री ग्रेड

- A

Trade Information

- Minimum Order Quantity

- 10 Kilograms

- आपूर्ति की क्षमता

- प्रति दिन

- डिलीवरी का समय

- दिन

About

Phosphor bronze rods are durable copper alloys containing tin and a small amount of phosphorus, which increases their strength, corrosion resistance, and wear resistance. Known for high fatigue strength and elasticity, these rods are excellent for springs, bearings, and gears. Their fine grain structure and good formability make them suitable for a wide range of industrial, electrical, and marine applications, such as fasteners, contacts, and marine hardware. The addition of lead in specific grades enhances machinability.Phosphor bronze is used in a wide range of applications, includingmusical instrument strings, electrical components like connectors and relays, bearings and bushings in industrial and automotive settings, and for springs and fastenersdue to its excellent strength, corrosion resistance, fatigue strength, and durability.Its ability to maintain mechanical properties under stress makes it ideal for high-performance and long-lasting products.- Used for high-quality, durable acoustic guitar and saxophone components and strings.

- Found in electrical connectors, circuit breaker contacts, fuse clips, and relay contacts for its conductivity and reliability.

- Essential for heavy machinery parts such as gears, bushes, and bearings where wear resistance and strength are crucial.

- Utilized for wear-resistant parts like bushings and rods in vehicles and aircraft.

- Its superior corrosion resistance makes it suitable for marine applications like propellers, shafts, and bearings.

- Used to make components like cotter pins, lock washers, and general hardware due to its strength and ability to resist mechanical fatigue.

- Its ductility, non-magnetic properties, and fatigue resistance make it suitable for a variety of springs, including those for indicating instruments.

Superior Strength and Versatility

Engineered from high-grade phosphor bronze, these rods are designed for robust performance in both construction and industrial settings. The combination of hardness and resilience ensures reliability in a range of demanding environments, making them highly sought after in factory and site applications.

Precision Manufacturing and Polished Finish

With a polished surface and round shape, every rod is meticulously manufactured to meet industrial standards. Available in diameters from 3 mm up to 100 mm and a standard length of 3 meters, these rods offer consistent quality and a professional finish, enhancing both appearance and performance.

FAQs of Phosphor Bronze Rod:

Q: How are phosphor bronze rods with Grade C544 used in construction and industrial sectors?

A: Phosphor bronze rods of Grade C544 are commonly employed for making bushings, bearings, electrical connectors, and shafts, thanks to their excellent wear and corrosion resistance, as well as reliable conductivity in critical construction and industrial machinery.Q: What are the primary advantages of choosing a polished, round phosphor bronze rod for industrial use?

A: The polished, round surface ensures smooth installation and operation, reducing friction and wear. Additionally, phosphor bronzes inherent strength and resistance to corrosion provide lasting performance even in harsh environments.Q: When is it advisable to select a rod diameter within the 3100 mm range?

A: Selecting a diameter between 3 and 100 mm depends on the projects mechanical demands, load requirements, and the specific application, with smaller diameters often suited for precision components, while larger sizes offer increased strength for heavy-duty tasks.Q: Where can I source phosphor bronze rods with these specifications in India?

A: These phosphor bronze rods are widely available across India from trusted dealers, manufacturers, exporters, importers, suppliers, traders, and wholesalers, making it easy to obtain them for varying scales of industrial and construction projects.Q: What is the process involved in manufacturing a high-quality phosphor bronze rod?

A: High-quality rods are produced through controlled alloying, extrusion or rolling, and precision machine finishing. The process ensures uniformity, strength, and the polished surface needed for demanding applications.Q: How does the material grade (A, C544) impact the rods performance?

A: Grade A and C544 indicate superior composition and quality, directly enhancing the rods strength, durability, and resistance to wear, making it ideal for challenging industrial and structural settings.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें