Price 280.0 आईएनआर/ टुकड़ा

MOQ : 100 टुकड़ाs

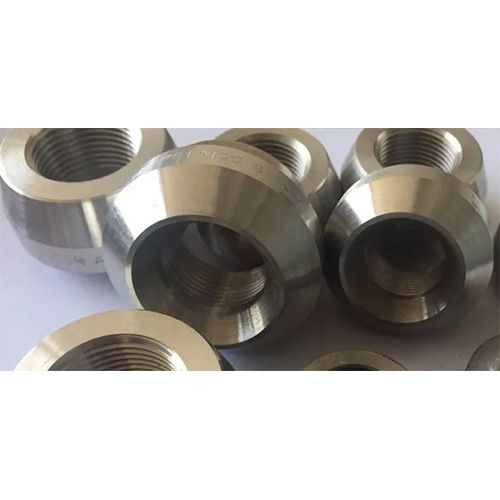

Specification

- सतह की फ़िनिश

- Polished

- उपयोग

- Commercial

- शेप

- Round

- मटेरियल

- Stainless Steel

- एप्लीकेशन

- Industrial

- टाइप करें

- फिनिशिंग

- साइज

- Standard

- ग्रेड

- SS 316-316L-316Ti

Trade Information

- Minimum Order Quantity

- 100 टुकड़ाs

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- दिन

About

SS 316, 316L, and 316Ti are austenitic stainless steel grades with chromium, nickel, and molybdenum for high corrosion resistance, particularly against chloride pitting. Forged fittings are durable, high-pressure components shaped by heating and forming. 316L's lower carbon content improves weldability, while 316Ti's titanium enhances stability at high temperatures. These fittings offer excellent ductility, strength, and durability, making them ideal for demanding applications in industries like petrochemicals, pharmaceuticals, and oil and gas.

-

A chromium-nickel-molybdenum alloy, chosen for its superior corrosion and high-temperature resistance.

-

Involves heating the metal and shaping it to create strong, durable components that can withstand high pressure and temperature.

-

Enhanced by molybdenum, providing strong resistance to pitting and crevice corrosion, especially in chloride environments.

-

Possess high tensile strength and excellent ductility, ensuring reliable performance in demanding applications.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in स्टेनलेस स्टील जाली फिटिंग Category

एसएस 317-317L जाली फिटिंग

मूल्य या मूल्य सीमा : आईएनआर

ग्रेड : औद्योगिक

मूल्य की इकाई : किलोग्राम/किलोग्राम

साइज : भिन्न उपलब्ध

न्यूनतम आदेश मात्रा : 100

माप की इकाई : किलोग्राम/किलोग्राम

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें