Price 350.0 आईएनआर/ टुकड़ा

MOQ : 100 टुकड़ाs

Specification

- मटेरियल

- टाइप करें

- स्टैण्डर्ड

- साइज

- 1/8" NB to 4" NB

- ग्रेड

- SS 347-347H

Trade Information

- Minimum Order Quantity

- 100 टुकड़ाs

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- दिन

About

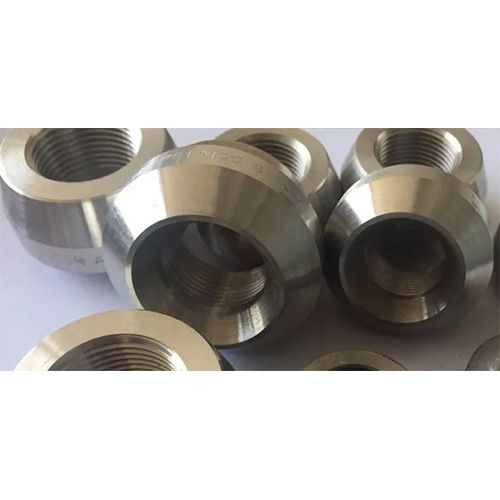

SS 347 forged fittings arehigh-pressure pipe connectors made from stabilized stainless steel alloy, offering excellent resistance to intergranular corrosion and carbide precipitation, especially at high temperatures.Thecolumbiumcontent provides superior resistance to stress rupture and high-temperature creep.These durable, leak-proof fittings are used to change pipe direction, join pipes, and split flows in vital industries like petrochemicals and paper mills, ensuring secure and reliable system connections

-

Resistant to issues like carbide precipitation, making them ideal for high-temperature applications.

-

Excellent resistance to intergranular corrosion and general aqueous corrosion.

-

Possess high tensile strength and creep resistance for demanding applications.

-

The inclusion of columbium (niobium) stabilizes the steel, preventing sensitization and improving high-temperature properties.

Premium Quality and Standards

Engineered using superior SS 347/347H material, these forged fittings undergo stringent quality controls and adhere to international standards like ASME B16.11 and BS3799. Their robust construction ensures reliable performance in challenging environments, making them suitable for critical applications in refineries, chemical plants, and more.

Versatile Range and Applications

Available in sizes from 1/8 NB to 4 NB, SS 347 forged fittings come in a variety of types, including socketweld and screwed-threaded ends (NPT or PT). Their versatility allows seamless integration into pipes and systems that require high corrosion resistance and mechanical strength, providing significant operational advantages.

FAQs of SS 347 Forged Fittings:

Q: How are SS 347 Forged Fittings manufactured?

A: SS 347 Forged Fittings are produced through a forging process in which heated stainless steel grade 347 or 347H is shaped under high pressure to achieve the required specifications. This process enhances their strength and grain structure, making them suitable for demanding industrial uses.Q: What standards do SS 347 Forged Fittings comply with?

A: These fittings conform to several international standards such as ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, MSS-SP-97, and BS3799, ensuring reliable quality and consistency for various industrial requirements.Q: Where are SS 347 Forged Fittings typically used?

A: They are commonly utilized in high-temperature and high-pressure piping systems, particularly in industries like petrochemical, oil and gas, power generation, and chemical processing, where excellent chemical resistance is essential.Q: When should SS 347H forged fittings be chosen over standard 347?

A: SS 347H forged fittings are specifically selected when applications demand enhanced high-temperature strength, as the H variant features a higher carbon content improving creep resistance and mechanical performance above 500C.Q: What benefits do socketweld and screwed-threaded fittings offer?

A: Socketweld fittings provide a strong, leak-proof joint suitable for high-pressure applications, while screwed-threaded (NPT/PT) fittings offer easier installation and dismantling, making them ideal for low to medium pressure piping systems.Q: What is the recommended usage process for these fittings?

A: For optimal performance, ensure precise measurement, prepare the pipes with compatible ends, and follow proper welding or threading procedures as per standards. Regular inspection and proper torque application ensure longevity and safe operation.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in स्टेनलेस स्टील जाली फिटिंग Category

एसएस 317-317L जाली फिटिंग

माप की इकाई : किलोग्राम/किलोग्राम

न्यूनतम आदेश मात्रा : 100

साइज : भिन्न उपलब्ध

मूल्य या मूल्य सीमा : आईएनआर

ग्रेड : औद्योगिक

मूल्य की इकाई : किलोग्राम/किलोग्राम

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें