Price 300.0 आईएनआर/ टुकड़ा

MOQ : 50 टुकड़ाs

Specification

- मटेरियल

- ,

- साइज

- 1/8" NB to 4" NB

- ग्रेड

- SS 321-321H

Trade Information

- Minimum Order Quantity

- 50 टुकड़ाs

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- दिन

- मुख्य घरेलू बाज़ार

- ,

About

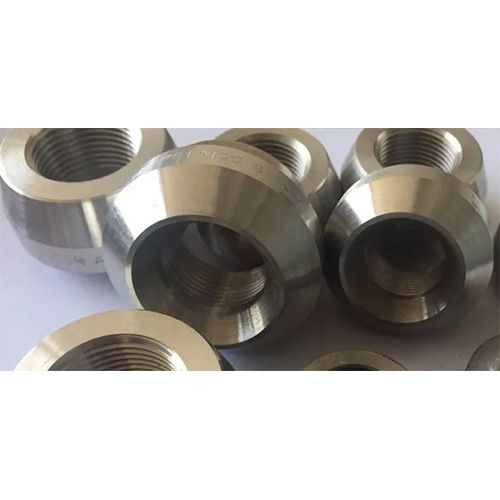

Standard Specification For Stainless Steel ASTM A182 321 / 321H Forged Pipe Fittings

Specifications :ASTM A182 & ASME SA182

Standard :ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Size :1/8 NB to 4 NB (Socketweld & Screwed-Threaded)

Class :2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS

Type :Socketweld Fittings, Screwed-Threaded Fittings

Chemical Composition of Grade 321 / 321H Stainless Steel High Pressure Fittings

| Grade | C | Mn | Si | P | S | Cr | N | Ni | Ti |

| SS 321 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 - 19.00 | 0.10 max | 9.00 - 12.00 | 5(C+N) 0.70 max |

| SS 321H | 0.04 0.10 | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 - 19.00 | 0.10 max | 9.00 12.00 | 4(C+N) 0.70 max |

Mechanical Properties of ASTM A182 SS 321 / 321H Forged Pipe Fittings

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1457 C (2650 F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

Precise Engineering for Extreme Conditions

SS 321-321H forged fittings are crafted to withstand high temperatures and harsh environments. Their stabilized alloy composition ensures minimal carbide precipitation, providing durability and long service life. These fittings have excellent mechanical properties, ideal for industrial piping systems in India and beyond.

Wide Range of Sizes and Types

Available in sizes from 1/8" NB to 4" NB, SS 321-321H forged fittings offer flexibility for varied applications. With multiple types including h, e, r, \ , and n, users can select configurations to match specific piping layouts, ensuring compatibility and ease of installation.

FAQs of SS 321-321H Forged Fittings:

Q: How are SS 321-321H forged fittings manufactured?

A: SS 321-321H forged fittings are produced using high-quality stabilized stainless steel through forging processes, ensuring superior strength. Precise forming techniques create different types like h, e, r, \ , and n, meeting industry standards and application needs.Q: What benefits do SS 321-321H forged fittings offer over other grades?

A: These fittings provide excellent resistance to corrosion and scaling, especially at elevated temperatures. The stabilization against chromium carbide formation enhances their reliability in environments prone to thermal cycling.Q: When should SS 321-321H forged fittings be used?

A: They are most suitable for high-temperature, high-pressure piping systems in industries such as chemical processing, power generation, and oil and gas, where resistance to heat and corrosion is essential.Q: Where can I source SS 321-321H forged fittings in India?

A: SS 321-321H forged fittings are available through various Indian dealers, distributors, manufacturers, exporters, importers, suppliers, traders, and wholesalers. These channels ensure wide accessibility for industrial buyers.Q: What is the typical process for surface treatment on SS 321-321H forged fittings?

A: Surface treatments often include cleaning, pickling, and passivation to enhance corrosion resistance and achieve a desired finish. These processes prepare the fittings for demanding industrial applications.Q: How do SS 321-321H forged fittings improve piping system longevity?

A: By leveraging stabilized stainless steel and advanced forging methods, these fittings minimize the risk of scaling, corrosion, and mechanical failure, contributing to longer-lasting, safer piping infrastructures.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in स्टेनलेस स्टील जाली फिटिंग Category

एसएस 317-317L जाली फिटिंग

ग्रेड : औद्योगिक

मूल्य की इकाई : किलोग्राम/किलोग्राम

न्यूनतम आदेश मात्रा : 100

माप की इकाई : किलोग्राम/किलोग्राम

मूल्य या मूल्य सीमा : आईएनआर

साइज : भिन्न उपलब्ध

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें