Price 400.0 आईएनआर/ Kilograms

MOQ : 100 Kilograms

Specification

- उपयोग

- Industrial

- मटेरियल

- साइज

- Standard

- ग्रेड

- SS302, SS304

- प्रॉडक्ट टाइप

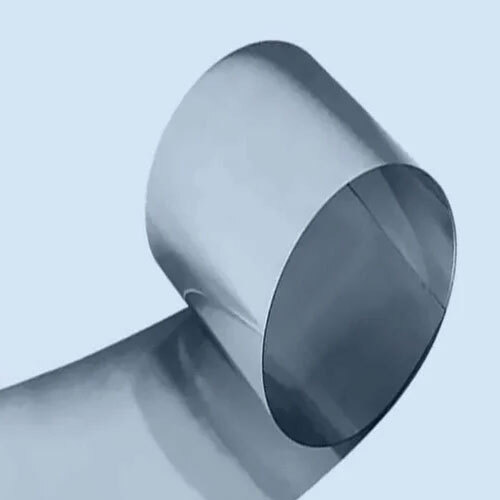

- Stainless Steel Shims And Foils

- रंग

- Silver

- कुंडल की लंबाई

- मीटर (m)

- एप्लीकेशन

- Industrial

Trade Information

- Minimum Order Quantity

- 100 Kilograms

- आपूर्ति की क्षमता

- प्रति दिन

- डिलीवरी का समय

- दिन

About

Shims are usedto fill gaps, correct misalignments, and provide precise spacing or leveling between objects.They are thin, often wedge-shaped, pieces of material like wood, plastic, or metal that are inserted to achieve a secure and accurate fit.Common applications include leveling furniture, installing doors and windows, aligning machinery, and making precise adjustments in construction and engineering.Steel shims are thin, flat pieces of metal, typically made of steel, that are used for various purposes in different industries. Also known as a spacer or packer, their primary function isto fill small gaps or spaces, allowing for precise adjustments and alignments in various applications.Precision and Durability

Manufactured with high-grade SS302 and SS304 stainless steel, our shims and foils provide outstanding strength and resistance to rust. Perfectly suited for industrial operations, each coil is meticulously rolled for optimal flatness and reliability. Their standard sizing and adaptable coil lengths ensure these products accommodate varied engineering and maintenance requirements.

Versatile Industrial Applications

These stainless steel shims and foils are widely used in machinery alignment, component spacing, and equipment maintenance. Their versatility makes them indispensable in sectors like automotive, electrical, and heavy engineering. Every product is engineered to maintain structural integrity while withstanding high-pressure or corrosive environments.

FAQs of Stainless Steel Shims And Foils:

Q: How are stainless steel shims and foils typically used in industrial settings?

A: Stainless steel shims and foils are primarily used for aligning machinery, filling gaps, providing accurate spacing, and protecting equipment surfaces in various industries such as automotive, manufacturing, and maintenance.Q: What grades of stainless steel are available for these shims and foils?

A: We offer shims and foils manufactured from SS302 and SS304 stainless steel, both known for their exceptional corrosion resistance, strength, and suitability for diverse industrial applications.Q: When should stainless steel shims and foils be used over alternative materials?

A: These products should be selected when superior resistance to rust, high temperatures, and mechanical strength is required, especially in environments where longevity and reliability are critical.Q: Where can I source these stainless steel shims and foils in India?

A: We operate across India as a dealer, distributor, exporter, importer, manufacturer, supplier, trader, and wholesaler, supplying to various industries nationwide.Q: What is the standard coil length and size availability for these products?

A: Our stainless steel shims and foils come in standard sizes and coil lengths ranging between 50 to 100 meters, facilitating easy adaptation to multiple industrial requirements.Q: Can you explain the manufacturing process for these stainless steel shims and foils?

A: The shims and foils are produced by cold rolling SS302 or SS304 stainless steel into precise thicknesses, followed by cutting and surface finishing to meet industry standards and guarantee uniformity.Q: What are the main benefits of using stainless steel shims and foils in industrial applications?

A: The primary benefits include enhanced durability, consistent quality, resistance to wear and corrosion, and the ability to perform reliably in demanding operational environments.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें