Price 400.0 आईएनआर/ टुकड़ा

MOQ : 50 टुकड़ाs

Specification

- मटेरियल

- , , , , , , , , , , , , , , , , , ,

- साइज

- Standard

- ग्रेड

- SS 904L

Trade Information

- Minimum Order Quantity

- 50 टुकड़ाs

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- दिन

- मुख्य घरेलू बाज़ार

- ,

About

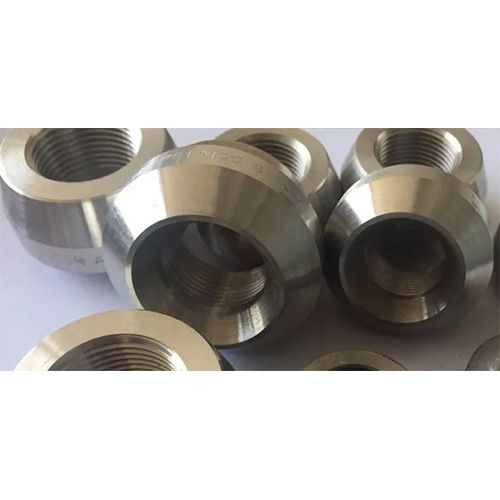

Standard Specification For Stainless Steel ASTM B649 904L Forged Pipe Fittings

Specifications :ASTM B649 & ASME SB649

Standard :ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Size :1/8 NB to 4 NB (Socketweld & Screwed-Threaded)

Class :2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS

Type :Socketweld Fittings, Screwed-Threaded Fittings

Chemical Composition of Grade 904L Stainless Steel High Pressure Fittings

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Cu |

| SS 904L | 0.020 max | 2.00 max | 1.00 max | 0.040 max | 0.030 max | 19.00 23.00 | 4.00 5.00 max | 23.00 28.00 | 1.00 2.00 |

Mechanical Properties of ASTM B649 SS 904L Forged Pipe Fittings

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.95 g/cm3 | 1350 C (2460 F) | Psi 71000 , MPa 490 | Psi 32000 , MPa 220 | 35 % |

Exceptional Corrosion Resistance

SS 904L forged fittings are engineered to withstand highly corrosive environments, making them a top choice in chemical processing, pharmaceuticals, and marine industries. Their robust chemical composition, enhanced by specialized surface treatments, provides reliable protection against pitting, crevice corrosion, and stress corrosion cracking.

Wide Availability Across India

Sourced from experienced manufacturers, distributors, and suppliers, SS 904L forged fittings are easily accessible throughout India. Their popularity among exporters and importers ensures a consistent supply chain for both domestic and international projects, catering to a wide range of industrial applications.

FAQs of SS 904L Forged Fittings:

Q: How are SS 904L forged fittings manufactured?

A: SS 904L forged fittings are produced through a forging process that involves shaping the alloy under high pressure and temperature. This method improves the materials mechanical strength and structural integrity, resulting in fittings capable of enduring demanding industrial environments.Q: What industries commonly use SS 904L forged fittings?

A: Industries such as chemical processing, oil and gas, pharmaceuticals, and marine engineering frequently utilize SS 904L forged fittings due to their superior resistance to acids, chlorides, and other corrosive agents.Q: When should I choose SS 904L over other stainless steel grades?

A: SS 904L is ideal when your application requires exceptional resistance to aggressive chemical environments, particularly those with sulfuric or hydrofluoric acid. If your project demands longevity and durability in such conditions, SS 904L is an optimal choice.Q: Where can I purchase SS 904L forged fittings in India?

A: You can buy SS 904L forged fittings from authorized dealers, distributors, exporters, importers, manufacturers, suppliers, traders, and wholesalers across India, providing reliable access to standard sizes and surface treatments as per your requirements.Q: What surface treatments are available for SS 904L forged fittings?

A: Common surface treatments include galvanizing, pickling, annealing, and passivation. These treatments improve the fittings tolerance to corrosion and enhance its overall lifespan, making them better suited for harsh service conditions.Q: How do SS 904L forged fittings benefit my industrial application?

A: These fittings offer excellent durability, resistance to corrosion and scaling, and reliable performance under high pressure and temperature. Their robust design minimizes leakages, reduces maintenance costs, and prolongs the service life of your installation.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in स्टेनलेस स्टील जाली फिटिंग Category

एसएस 317-317L जाली फिटिंग

ग्रेड : औद्योगिक

मूल्य या मूल्य सीमा : आईएनआर

मूल्य की इकाई : किलोग्राम/किलोग्राम

न्यूनतम आदेश मात्रा : 100

माप की इकाई : किलोग्राम/किलोग्राम

साइज : भिन्न उपलब्ध

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें